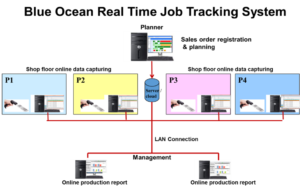

Blue Ocean Job / Lot Tracking System

Challenges

In discrete manufacturing the work moves through its routing from operation to operation and the Production Order is updated with progress; this could include quality results or sign offs. Job tracking in this environment can be a problem. Even today, frequently, the Production Order is often a printed document (sometimes called a Traveller) that is physically issued to the line and moves with the work.

When there is complex routing through many processes, and many jobs in production. Nobody can see exactly where each job is, how far it has progressed and what is left to do.

Solutions

Blue Ocean job tracking system will help manufacturer to perform the following task :

- Create orders and assign to production lines. Alternatively, if the production planning and scheduling module is used then Production Orders can be created and scheduled in advance or automatically downloaded from ERP systems

- Download the routings from the ERP system as master data, reducing the amount of data capture required on the shop floor

- Split an order up into a series of jobs, for each operation or to split a large order into smaller orders.

- Jobs are started and ended at the line by operators, either manually or by using bar-code scanners. In some cases, where the infrastructure permits it is possible to take signals directly from the PLC.

- Capture information like planned quantity, actual quantity, start time, end time and duration.

- Run numerous reports that related to Production Orders, for example their progress, history and exceptions.

- Upload to ERP the progress of Production Orders.

Benefits

- Visibility – view work in progress; know exactly the status of each order. This is especially useful in complex discrete processes, or job shops, where it can be hard to see at what stage the work is.

- Tractability – all data recorded in the production run (job) is tied tack to the Production Order, for example the parts made, the order, the production line, shift, the start and end times, the person responsible.

- Go paperless – stop issuing paper work instructions and all that goes with it from issuing to filing

- Improve shop management – through greater visibility, see the bottlenecks and hold-ups.