Online Data Analysis

JMP / Minitab Online Data Analysis, Quality Monitoring & Process Trouble Shooting

Challenges

Very often, JMP / Minitab software users may ask the following questions

- Why can’t you enter data automatically from measuring equipment or other devices?

- Why can’t you update real-time SPC charts without manual data entry ?

- Why can’t you get real-time alarms so you can stop making bad product immediately, instead of waiting hours or even days to find a problem?

- Why can’t you scrub data as it is entered – forcing consistent spellings, identification numbers, and traceability information?

- Why can’t you generate online quality report automatically ?

Solutions

Now, with Blue Ocean Data Bridge ™ software, you can. It links to your process and measuring equipment to extract online data and delivers to JMP or Minitab in real time.

JMP / Minitab online data analysis system provides statistical decision-making at the point of production and delivers real-time,actionable information to operators, managers and engineers. It collects data from various sources such as measuring devices and process equipment. Through online data extraction and report generation, it enable engineers to detect, prevent, and/or resolve issues before waste occurs.

Benefits

a. Elimination of manual data entry

We automate data collection from multiple sources and enforce standardized data entry procedures for users. Our solutions help to ensure the reliability of your data. All of your process data is stored in server or standalone PC for easy retrieval, analysis and reporting.

b. Powerful online analytical tool

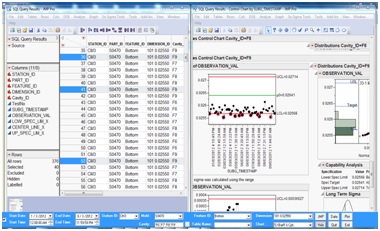

This combination of rich, reliable data and powerful analytical tools empowers our customers to reduce costs, cycle time, errors, and defects, and to increase profitability and customer satisfaction. Below are some of the examples of real time analysis reports.

- Linkage between control chart and data table enables you to perform process trouble shooting in an effective and efficient manner.

- Keep track the changes before and after process improvement – this feature enables you to justify the effectiveness of actions taken.

- Powerful root cause analysis : When there is excessive process variation or Cpk index is not satisfactory, JMP / Minitab armed with many powerful analytical tools to identify source of variation and help you to trigger appropriate improvement actions.

- Advance analysis : Through online data collection, the information of your process performance is in your finger tip. For example, when there is quality issue, you may perform one way ANOVA to find out whether there is significant difference among machines.