BO 202 – JMP Training : Design of Experiments (DOE) – 3 days

Introduction

Design of Experiments (DOE) is an off-line quality improvement methodology that dramatically improves industrial products and processes thus enhancing productivity and reducing costs. Input factors are varied in a planned manner to efficiently optimize output responses of interest with minimal variability.

This course will provide delegates with basic DOE knowledge & techniques that have been specifically designed to deal with common process optimization problems that encountered by engineers in industry. These techniques will be demonstrated by using JMP software with actual industrial data.

Learn how to

• Explain the fundamental principles of designed experiments

• Generate and analyze full factorial, fractional factorial, split-plot and screening designs, including designs with blocking factors.

• Create and analyze classic response surface designs

• Use the custom design tool

Training Approach

This practical course combines classroom teaching, practical exercises, and group discussion with actual factory based projects to provide a complete action learning experience. The course has been designed to enable all participants leave the training room with a set of new knowledge, tools, skills and direct experience of how to use JMP software to perform process and quality improvement in a real company setting.

Prerequisite: Statistical Data Analysis Through JMP software & Hypothesis Test, ANOVA & Regression Analysis

Training facilities: Computer installed with JMP Software and LCD projector

Course contents

DAY ONE

Section 1 : Introduction to Design of Experiment (DOE)

• What is DOE?

• Why do a designed experiment?

• DOE vs. One-Variable-At-A-Time

• The different stages of quality improvement

• Types of experiment

• The challenges faced by engineers

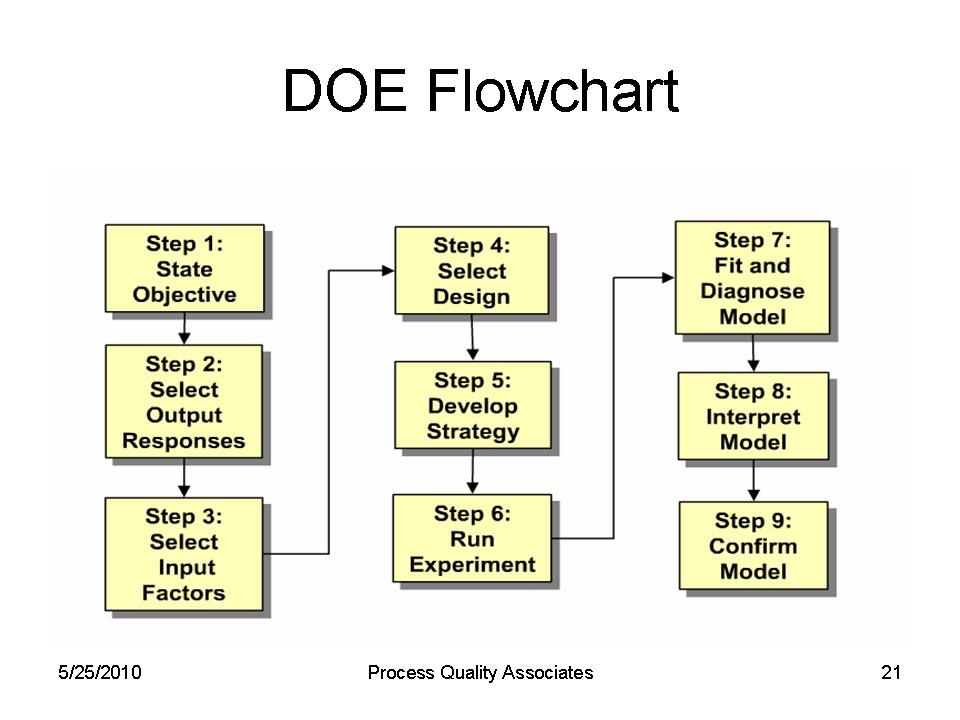

• Steps for DOE

• Practical examples

Section 2 : Full Factorial design and response optimization

• Factors vs response

• Completely randomized design

• Techniques to create factorial design

• Coded setting and orthogonal design

• Replicating & blocking the design

• Tree diagram

• Meaning of Main Effects and Interactions

• DOE modeling

• Un-coding the setting

• Cube plot

• Split plot

• Defining factor constraints

• Setup of Response optimizer & optimization plot

• Interpretation of results and identify necessary improvement actions

• Practical application exercise by using JMP software

DAY TWO

Section 3 : Screening Design

• Fractional vs full factorial design

• Confounding effect

• Design resolution

• Folding the design

• Center points, & residual plots

• Plackett –Burman design

• Prediction profiler

• Desirability function

• Practical application exercise by using JMP software

• DOE simulation game

DAY THREE

Section 4 : Response Surface Methodology (RSM)

• Basic concepts of RSM

• Application of RSM

• Shape of responses

• Central composite design

• Box-Behnken design

• Contour profiler with high low limits

• Response surface plot analysis

• Response optimization

• Interpretation of results and identify necessary improvement actions

• Custom and augment design

• Practical application exercise by using JMP software

Who should attend: Anyone who would like to understand and improve process design, such as engineers, scientists and Six Sigma practitioners.

Delivery: Classroom lecture, hands-on practice, simulation game, assignments and case studies.

Duration: 3 days (9am – 5pm)