Online Hardness Measurement System for Heat Treatment Process

Challenges

Very often, hardness tester is a piece of standalone measurement equipment. Once measurement is done, inspector will record down measurement data manually in QC form. This process has high chance of human error and it is not productive because the data will key in Excel or SPC software for plotting of SPC chart and calculation of Cpk. The SPC chart generated is not real time and most of the time the event is over once process abnormality is detected.

Very often, hardness tester is a piece of standalone measurement equipment. Once measurement is done, inspector will record down measurement data manually in QC form. This process has high chance of human error and it is not productive because the data will key in Excel or SPC software for plotting of SPC chart and calculation of Cpk. The SPC chart generated is not real time and most of the time the event is over once process abnormality is detected.

Solutions

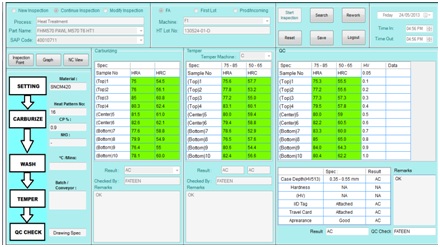

By having online hardness measurement system, the system will connect directly to hardness tester which allow the data to go to the system directly without any data entry. It allows instant plotting of SPC chart and calculation of Cpk. The system is designed to capture rework information for better process tractability. Relevant specification can be updated through the system with revision control. Drawing or defect picture can be up loaded to the system for easy reference. Various customized report is available to monitor the process performance.

- Elimination of manual data entry and human error.

- Better traceability : lot history can be traced easily especially when there is quality issue or customer complaint.

- Instant information on process performance for immediate actions and improvement.

- Real time SPC monitoring and Cpk report.

- Enable engineers to do more value added process improvement job instead of tedious report compilation.

- Better quality assurance and customer satisfaction.

- Management has complete picture on what happening in the shop floor (process control is transparent)